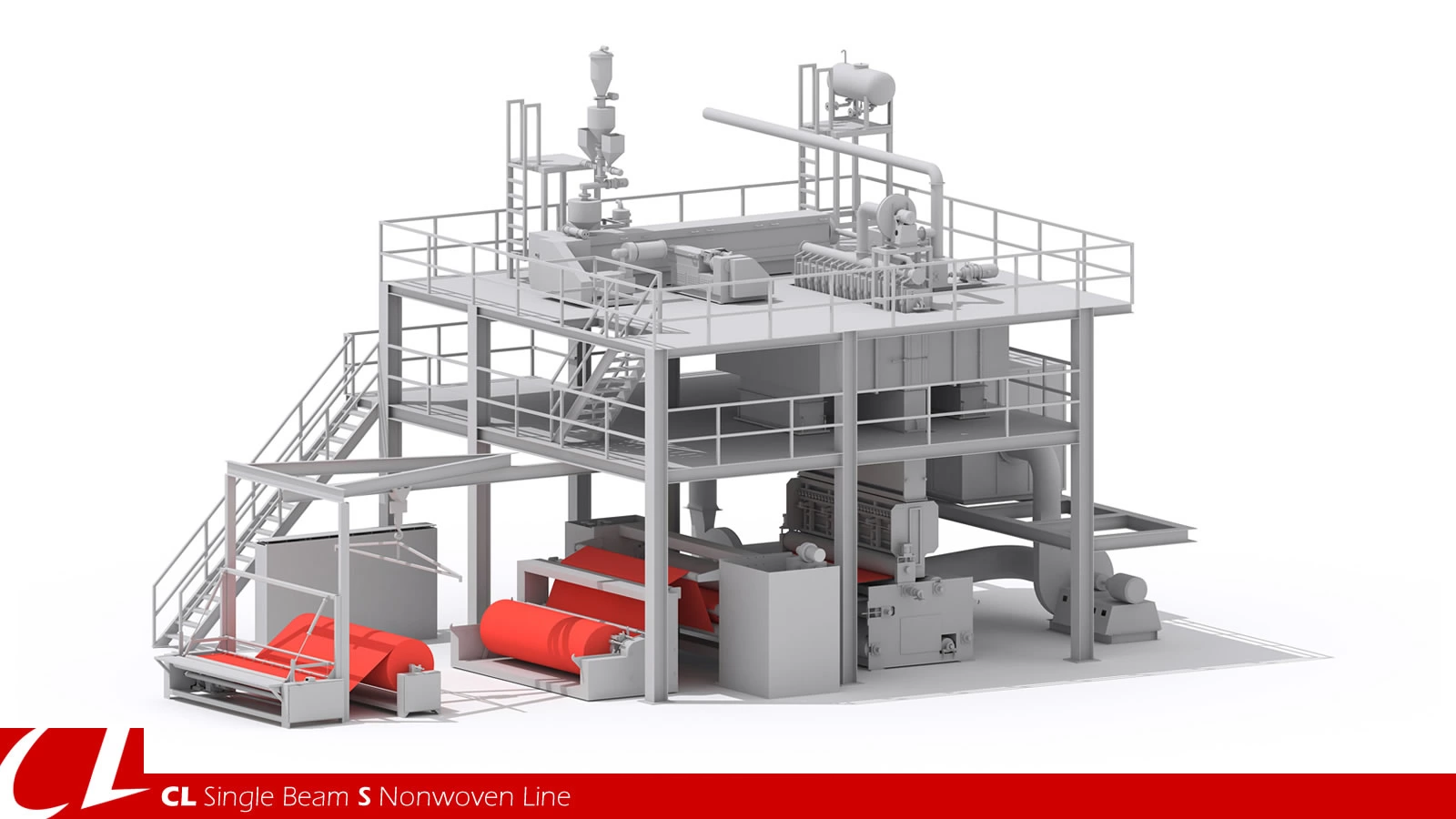

Single S Nonwoven Fabric Making Machine

In 1998, CL pioneered the development of China's first single-beam S spunbond line.

Our fabrics have since found extensive applications across a range of industries, such as packaging and agriculture. They are integral to the production of shopping bags, luggage and furniture linings, pocket springs, disposable bed sheets, shoe covers, fruit bags, crop protection materials, and much more.

Technical Specification

Part One : The Design Conception Of This Project Is As Following:

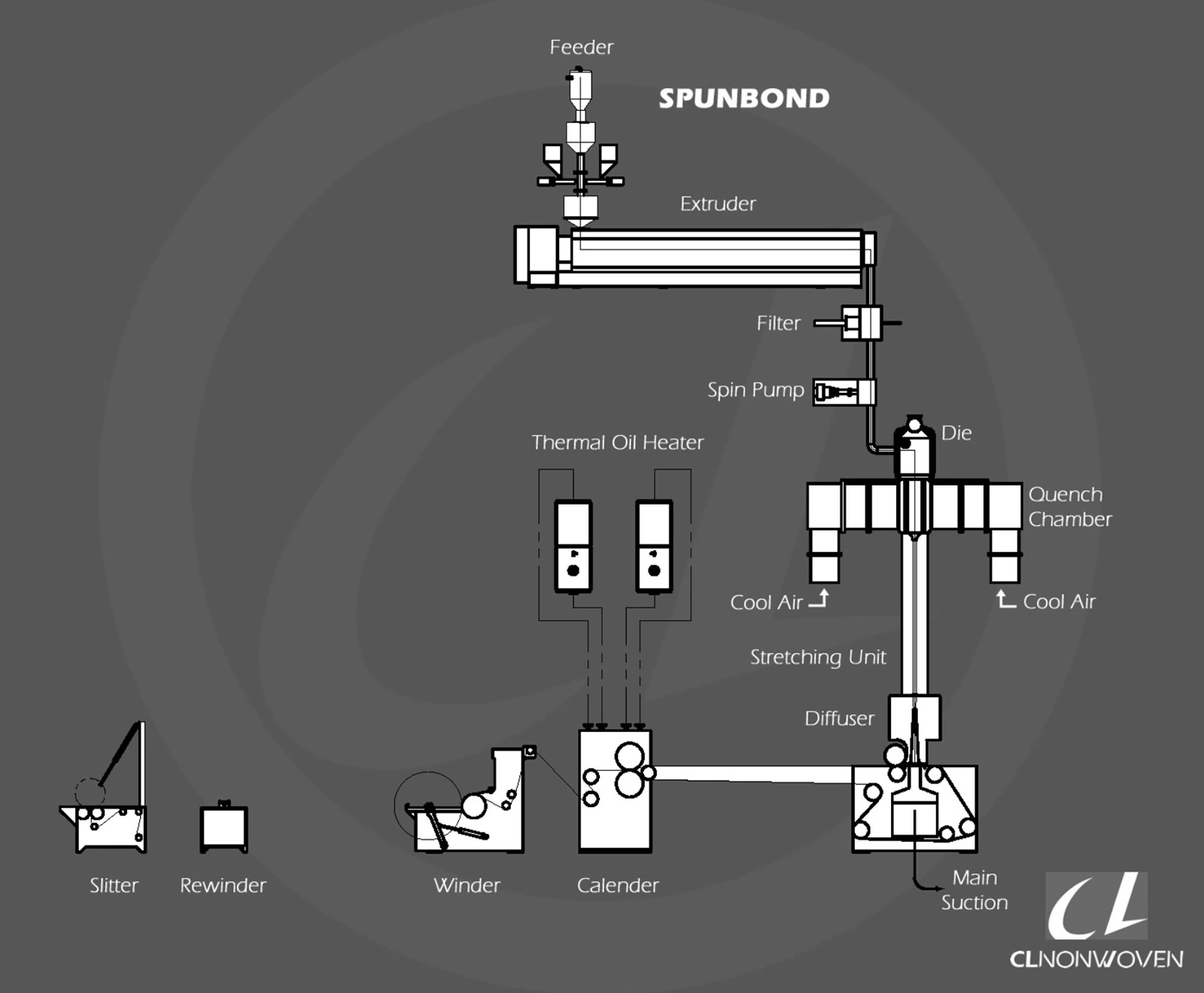

PP chips ---- Blending and Feeding --- Melting in the Extruder --- Prefiltration Recycled Materials

Masterbatch hoppers -- Spinning -- Cooling with the Side Wind -- Air Dragging ---Web forming -- Thermal bonding -- Winding -- Cutting -- End Products

- Engineering: Electricity supply and distribution, Air conditioner and Cooling system.

- Spinning : PP chips feeding, Extruding, pre- Filtration, Spinning

- Web: Web forming , Thermal bonding and Winding

- Cutting : Semi-manufactured goods, Cutting , Packing

Part Two: Products Specification And Quality Standard

- Products specification : Weight 10-180 g/gsm, width 1600/2400/3200/4200mm

- Quality Standard: According to the International standard of PP spunbond nonwovens.

- PP index: Homopolymer which is suitable for long fiber Polyproplene at MFI:25-40

- Air distribution : Uniform at the cross direction, Decreasing from the airjet to the web former at the machine direction.

- Calander (Thermal bondingWidth: 1600/2400/3200/4200mm

Roller Type: The up one surface is fluting and the down one surface is smooth. - Winding with online cutter: Max width: 1600/2400/3200/4200mm

- Off line slitter: CL latest

Part Three : Main Equipments

- Feeder air pump with the negative pressure, autocontrol for the up feeder.

- Extruder :droven by alternating current motor, autocontrol for the temperature and pressure.

- Blending system for the colorful PP articles: metering and blending automatically and exactly so as to make the color and luster uniform.

- Spinning manifold: with single die and module

- Heating system: heating extruder with electricity, heating the other parts with recycled heating system according to the customer requirement.

- Cooling system: this production using two sides air cooling system in order to make the full dragging and assure the fiber quality.

- Drawing machine: drawing and making the fiber thin with the cooling air.

- Web former: collecting the fiber with the help of the negative pressure drawing so as to get the continuous web. It is made of gear change mechanism, frame, transmission belt and air suction system.

- Transmission belt: carrying the web to the calander for thermalbonding.

- Calander: mainly for web consolidation. There will be some deformation and melting in the web under the condition of high pressure of heating.

- Winder: mainly for winding the thermal bond nonwovens to be a certain quantity. It is made of frame, friction roller, roller auto changing unit, rolling shaft, A/C motor and controlling system

- Offline slitter: Mainly for cutting the nonwovens according to the request of the customer such as length, width and weight.

- Assembly cleaning: through annealing oven and microwave oven. Checking the spinneret orifice with microscope.

| Effective Width | GSM Range | Max. Speed | Annual Capacity | Daily Capacity |

|---|---|---|---|---|

| 1600MM Line | 10-180 | 200 m/min | 1500 Tons/Year | 4 Tons/Day |

| 2400MM Line | 10-180 | 200 m/min | 2300 Tons/Year | 6 Tons/Day |

| 3200MM Line | 10-180 | 200 m/min | 3000 Tons/Year | 8 Tons/Day |

| 4200MM Line | 10-180 | 200 m/min | 4000 Tons/Year | 11 Tons/Day |

Single S Nonwoven Fabric Making Machine Process Flow